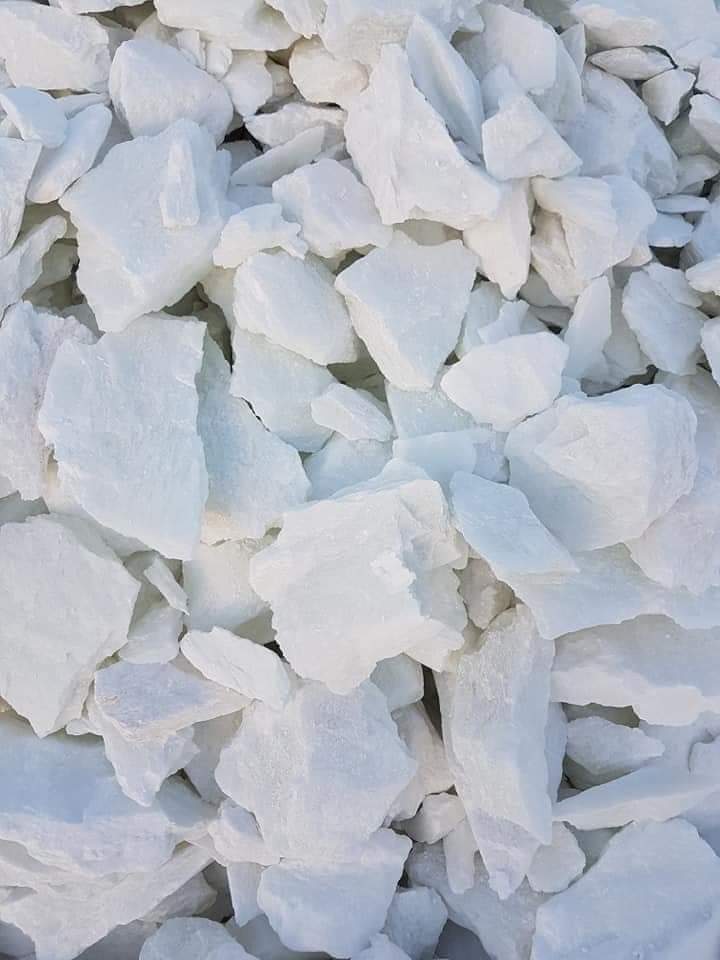

TALC

Technological Expertise

AFCHEMICAL Associated, the entire mining process is highly systematic.in 2006 the Afghanistan Government And International Donors USAID, United States Geological Servy Organization (USGS) initiated the process with potential areas of reserves to draw an estimation of quantities and quality of Talc mines in Afghanistan.

Our miners trained by international donors and by Afghanistan goverment Minstry of mine and petrolum workshop teams in ceminars and practically, We then engage controlled blasting practices using the most advanced equipments for mining and later transporting the ore of different qualities separately for sorting to the stockyards. the sorrting is manually and highly controlled by leader team of our company.

High Quality Reserves

According to Geological Servy of Soviet Union Specialist in 1970 And in 2003 United States Geological Servy Organization (USGS) estimated Afghanistan has over 61.5 million metric tons of reserves, which can be explored over a long period of time. With an annual crude extraction volume to the tune of 300,000 MT, from the finest talc deposits in the world, we are new and young in the exploration of talc lumps mining and Production of Talcum powder in Afghanistan.

Our mines are spread across five mining zones covering an area of 20 kilometer southern Nangarhar Province the world famous tunnels of TORRA BORA. Together they account for an annual production of 120,000 MT. The crude from these mines is renowned across the world for its purity and brightness 97% - 99%.

Grinding of Talc,Dolomit,and other minerals is done through state of the art technology including High Efficiency Jet Mills, Hammer Mills, Pulverisors, Classifiers and Compactors; thus ensuring consistent quality in terms of particle size distribution, optical properties and rheological properties.

Unique Feature of AFCHEMICAL AFTalc are:

• High whiteness & brightness

• High purity

• High lamellarity

• Free from Asbestos and heavy metals

PAINT & COATING

Talc is an ideal multi-functional pigment, filler and extender in water borne, solvent borne and powder-coat based architectural and industrial paints, where they improve mechanical properties, optical properties and production processes. They also bring benefits to color concentrates, enamels, varnishes, gel coats, inks, putties, body fillers, mortars and asphalts.

Talc is an ideal multi-functional pigment, filler and extender in water borne, solvent borne and powder-coat based architectural and industrial paints, where they improve mechanical properties, optical properties and production processes. They also bring benefits to color concentrates, enamels, varnishes, gel coats, inks, putties, body fillers, mortars and asphalts.

Key Attributes of our Talc:

Excellent whiteness and brightness.

Pure and soft.

Unique morphology of our Talc gives excellent colour and brilliance to paint.

Controlled oil absorption and viscosity.

Excellent hiding power.

Improves water, alkali & stain resistance.

Our ultrafine grades of Talc also help to partially replace TiO2.

Talc Helps:

Corrosion resistance & barrier properties

Hiding & TiO2 extender

Flatting - Matting

Mud cracking

Rheology

VOC reduction

Weather scrub color UV resistance

Our Recommended Application:

Architectural & Decorative paints

Industrial paints

Wood coatings

Color concentrates

Metal paints

Organic paints

Plastics

Talc is an excellent reinforcing filler in polypropylene and engineering thermoplastics for automotive parts, domestic appliances, E&E components and food packaging. They are used for antiblocking in polyethylene, restore mechanical properties to recycled plastics and are ideal nucleating agents in biopolymers and semi-crystalline polymers.

RUBBER

Talc being used in rubber threads , sheets, seals, hoses, membranes, cables, stoppers and tires to improve processing, impermeability, weathering, electrical properties, fire resistance and mechanical properties. Talc improves the dispersion of reinforcing fillers, reducing mixing time.

Key Attributes of our Talc:

High Purity

Excellent Whiteness and Brightness

Lamellar Structure.

Unique morphology of our Talc gives excellent mechanical property.

Silica-free and minimum iron content.

REACH exempted

Complying with USP, BP , EP

Talc Helps:

Mechanical properties

Partitioning agent

Partitioning agent

Permeability barrier

Processing aid

Synergism with carbon black

Our Recommended Application:

Rubber threads

Rubber Sheets, Hoses , Seals

Fire resistant wire & cable

Industrial mechanical goods

Pharmaceutical closures

Tires

POLYESTER PUTTIES

Talc is a very important functional filler in putty made of unsaturated polyester, e.g. for car and truck bodies. It is used here in proportions of upto 60% by weight. Thus, the quality of the putty ingredient “talc” has a significant effect on putty performance.

Key Attributes of our Talc:

Soft and Pure Talc

Controlled Low Oil Absorption.

Low Viscosity

Least amount of Acid soluble Contents.

ImprovesSandability:

The softness of pure talc leads to good sandability of polyester putties. It gives high-quality surface finish after sanding operations.

PotLife:

The pot life is adversely affected by the content of soluble contaminants. AFCHEMICAL Talc exhibits the least content of soluble HCl and offers the longest pot life.

Low and consistent oil absorption:

By means of double air classification, oversize particles and fine dust are removed. The lack of very fine particles results in talc products with low oil absorption. This enables the formulator to use less resin, which is both economical and environmentally friendly. This unique combination of properties has made Golcha Associated talc the most popular products for polyester putties worldwide

Adhesion and elasticity:

The highest elasticity is achieved with talcs of low oil absorption. At the same time, their lamellarity increases the adhesion to steel substrate.

Viscosity and fillling level:

Narrowly controlled particle size distribution ensures reproducible paint viscosity characteristics and enables high filler loadings to be achieved. Viscosity and filling level depend on the surface area and structure of the talc particles. Double classified means that the product has passed through two air classifiers, which remove coarse particles in the first step and ultrafines (dust) in the second step. The reduction of fines means that more talc can be added without increasing the viscosity.

Our Recommended Application:

Automotive Putty

Wall Putty

PAPER

Our Talc is highly lamellar and soft having 1 on the Mohs hardness scale. This natural property provides a series of benefits in papermaking and recommended to use as filler and pitch control.

Key Attributes of our Talc:

High Purity

Excellent whiteness and brightness. Product whiteness would be available in the range of 85% - 98%.

Lamellar structure.

Low abrasion index

As filler it gives excellent smoothness, porosity and opacity to paper in addition to reducing the cost. As compared to GCC it is less abrasive so it increases the wire and felt life.

To control Pitch and Stikies during the paper making process, oleo resinous droplets micro or colloidal in nature get added to the stream. These micro impurities can clog the paper machinery. Talc being hydrophobic absorbs these micro droplets or if the droplets are big then talc lamellae stick to their surface thus controlling their stickiness.

REFRACTORIES

Clay is used in the manufacturing of Refractory products combines BP Set, SW Pipes, Fire Bricks and Insulations Bricks.

The major properties to use Clay are:

An ability to resist the effects of extremely high temperatures

Clay has high content of Alumina, so increases resistance.Our Talc enhances the performance of inks and makes for an ideal filler and extender in water-borne and solvent-borne inks.

Key Attributes of our Talc:

High purity combined with excellent whiteness.

Precise particle size distribution. We offer the finest particle size product up to D(50): 1.5 microns.

As a filler or extender it delivers various advantages as listed below:

Increase dry hiding and opacity

Makes cost effective TiO2 extenders reducing costs

Improves matting - flatting effect

Increases ink transfer, results in a clean print

Decreases clogging

Provides good adhesion to ink films

Reduces blade wear

Reduces blade wear

SOAP & DETERGENT

AFTALC is cost-effective filler in soaps and syndets to provide a creamier lather, improve foaming, give a soft and silky skin feel; AFTALC is substitute to expensive base oils, which helps manufacturers to cut final product costs.

Key Attributes of our Talc:

High Purity

Soft and smooth

High whiteness

I

n the Soap & Detergent industry, ball clay is used as performance filler which reduces product cost.

n the Soap & Detergent industry, ball clay is used as performance filler which reduces product cost.

AGROCHEMICALS

T alc powder used as an inert carrier for fertilizers, agrochemicals and pest control preparation .Talc acts as an excellent coating agent, preventing caking and improving fertilizer flow, reducing water pick-up, protecting from crystal bridge formation and reducing dust. In olive oil production talc act as an extremely efficient processing aids for increasing oil yield. They are environment friendly alternatives to chemicals for the UV protection of fruit crops.

alc powder used as an inert carrier for fertilizers, agrochemicals and pest control preparation .Talc acts as an excellent coating agent, preventing caking and improving fertilizer flow, reducing water pick-up, protecting from crystal bridge formation and reducing dust. In olive oil production talc act as an extremely efficient processing aids for increasing oil yield. They are environment friendly alternatives to chemicals for the UV protection of fruit crops.

Key Attributes of our Talc:

High Purity

Lamellar Structure

Complying with USP, BP , EP

Our ultrafine grades having particle size top cut:

5 microns gives excellent coating ability.

T alc Helps:

alc Helps:

Anticaking agent

Die lubricant

Dispersing agent

Dust reduction

Flowability

Inert carrier

Processing aid (olive oil)

Our Recommended Application:

Fertilizer

Fruit production

Olive oil production

Seed coatings

CERAMICS & ENGINEERED STONES

Talc can be used in the manufacturing of ceramic products such as bathroom fixtures, ceramic tiles, pottery and dinnerware. When used as a filler in ceramics, talc can improve the firing characteristics of the greenware and the strength of the finished product. Being used as a flux agent for glaze with low iron content, reduces the melting point of ceramic glazes and improves their vitrifications. When used as a flux agent for ceramic by reducing the process temperature and the firing time, talc reduces the processing costs.

Key Attributes of our Talc:

Low Iron Content

Optimum after firing whiteness

Unique morphology of our Talc offers excellent mechanical property and better dimensional stability.

Talc Helps:

F luxing agent

luxing agent

Frit, glaze & engobe properties

Glaze-body fit

Mechanical properties

Thermal shock resistance

Our Recommended Application:

Automotive cordierite ceramics

Cordierite - mullite refractories

Electroceramics

Frits, glazes & engobes

Glazed floor tiles

Large format & thin tiles

Porcellanato stoneware tiles

Sanitaryware

Tableware

White body earthenware tiles

Our Products for Ceramic Application:

HGM 100

Ceramic Mix for body application

Clay

Clay is used in the manufacturing of ceramics products such as bathroom fixtures, ceramic tile, pottery and dinnerware. When used as filler in ceramics, clay improves:

Plasticity and Strength

It increases Bonding properties

E nsures perfect finish in Glaze / engobes

nsures perfect finish in Glaze / engobes

Key Attributes of our Clay:

High Plasticity Clay

Optimum after firing whiteness

Recommended Application:

Ceramic Vitrified Tiles

Ceramic – Wall-Floor Tiles

Sanitary ware

Tableware

Potter ware

White body earthenware tiles

COSMETIC

S oft to the touch and chemically inert, talc has been used as a body powder and is an ideal carrier for perfumes. Our Talc provides the silkiness in blushers and eye shadows, the transparency of foundations and the sheen of powder compacts.

oft to the touch and chemically inert, talc has been used as a body powder and is an ideal carrier for perfumes. Our Talc provides the silkiness in blushers and eye shadows, the transparency of foundations and the sheen of powder compacts.

Key Attributes of our Talc:

High Purity

Soft and Silkiness

Excellent Whiteness & Brightness

REACH exempted

Complying with USP, BP , EP

Talc Helps:

Fragrance carrier

Inert carrier

L ower formulation cost

ower formulation cost

Oil-base replacement

Optical properties

Pigment extender

Softness

Our Recommended Application:

Body Perfumery talc Powder

Cream

Compact Powder

Foundation

Eye Shadow

Baby Talc

ELECTRICAL INSULATORS

In the Insulator Industry, ball clay is used as performance filler which strengthen product, with high fire resistance value, better insulation from high voltage current.

Our Products for Insulator Application:

SUPERPLAST

SAINIFILL